DRINKING WATER

THE UNIQUE CHALLENGES OF DRINKING WATER RESERVOIRS

Utility managers face distinct challenges in maintaining drinking water reservoirs compared to recreational ponds and lakes.

The problems are often more subtle and less visually apparent than extensive aquatic weed growth or large-scale algal blooms. As public utilities, reservoirs are subject to more stringent management standards and must meet requirements for a range of water quality parameters that are not typically a concern for recreational water bodies.

Additionally, utilities must maintain consistent water quality throughout the year and protect their water sources from seasonal extremes.

drinking_water_1

Toa Vaca, Puerto Rico, Drinking Water Reservoir, 836 acres

To ensure a reservoir is suitable for public water supply, its quality must be consistent throughout the water column, with a proper balance of nutrients and dissolved oxygen distributed evenly.

High levels of algae and weeds in the upper water column and deoxygenated water in the lower column can create numerous issues. In the upper column, excessive aquatic plants and algae can clog plant intakes and filtration equipment. In the lower column, geosmins, high levels of dissolved metals, high organic content, and hydrogen sulfide can lead to taste and odor problems that result in customer complaints.

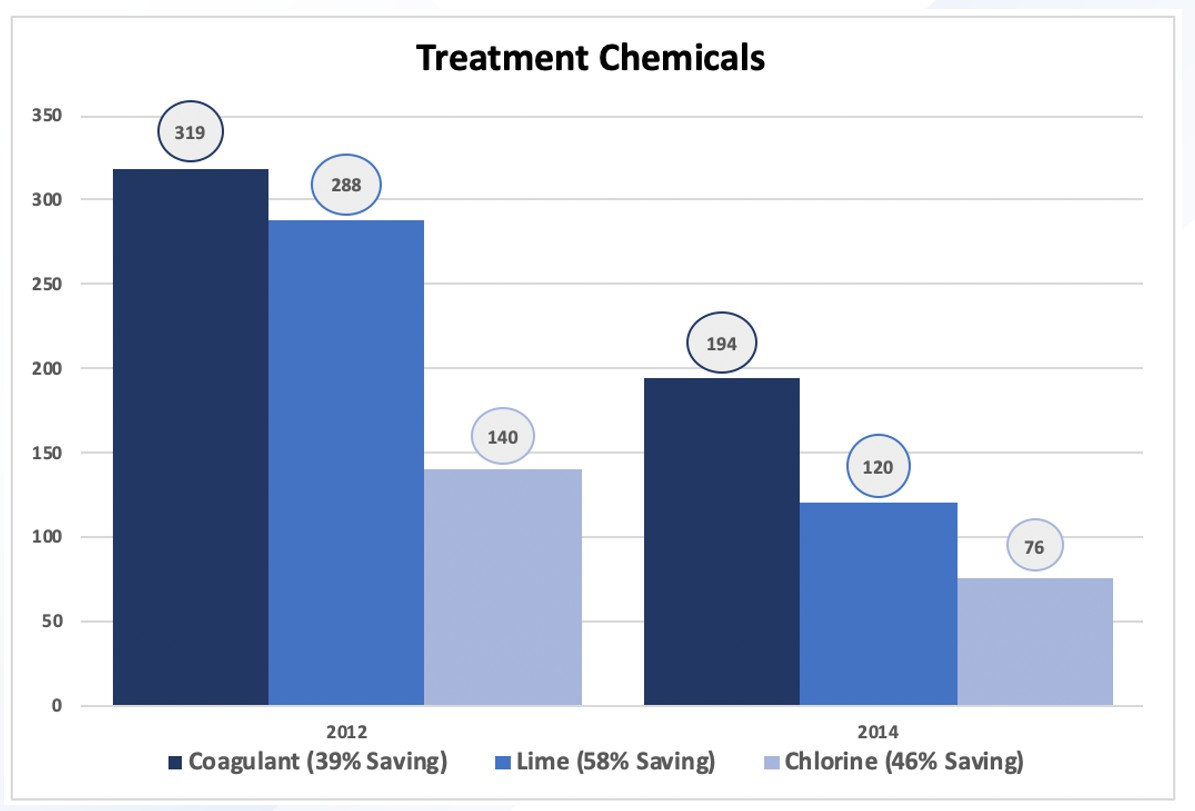

Conventional approaches to addressing inconsistent water quality often involve the use of treatment chemicals and auxiliary treatment processes, which can increase plant operation costs and, in the case of chemical usage, may generate potentially harmful byproducts.

CLEAN-FLO’S APPROACH TO RESERVOIR RESTORATION

Clean-Flo has a deep understanding of the exacting requirements utilities face and has been delivering effective solutions for decades.

Our approach utilizes natural, chemical-free processes to address the root of the problem, rather than merely treating symptoms. We focus on correcting the reservoir’s balance of nutrients, organic matter, and dissolved oxygen, and promoting desirable aquatic organisms that help maintain a natural balance in the reservoir’s ecosystem. Specifically, our methods improve reservoir restoration by:

– Normalizing pH

– Increasing dissolved oxygen

– Reducing levels of manganese and iron

– Reducing algae

– Reducing turbidity

– Reducing total organic carbon (TOC) and dissolved organic carbon (DOC)

– Reducing nitrates and nitrites

– Eliminating hydrogen sulfide and geosmins

The benefits of Clean-Flo’s approach include:

– More consistent water quality

– Better risk management

– Reduced chemical usage

– Lower operating costs of treatment plants

– Reduced disinfection byproducts such as trihalomethanes

CASE STUDY: TOA VACA RESERVOIR, PUERTO RICO

Toa Vaca reservoir in Puerto Rico, built in 1972 with an expected lifespan of 300 years, covers 836 acres and is over 51 meters deep when full. By 1985, its capacity had been reduced by 13.5% due to sediment buildup, and the reservoir showed the first serious symptoms of water quality deterioration due to eutrophication.

The intake tower consists of six gates, numbered one to six from bottom to top. As early as 2009, due to eutrophication, only the upper two abstraction points (gates five and six) could be used to draw water for purification treatment.

Water from deeper gates was untreatable due to high levels of manganese and contaminants causing foul tastes and odors, such as geosmins and hydrogen sulfide. However, drawing water from the upper levels also presented problems, as high algae levels clogged filters and required the use of high levels of flocculants and chlorine in the purification process, generating excessive levels of trihalomethanes (TTHMs), a carcinogenic byproduct of chlorination.

By 2012, high levels of manganese, hydrogen sulfide, and toxic cyanobacteria in the upper water column made it increasingly difficult to produce potable water that met regulated standards.

The future prognosis for the reservoir was poor, with fish kills becoming so common that recreational fishermen and birds of prey had abandoned the reservoir.

CLEAN-FLO’S SOLUTION

Recognizing that conventional aeration would not achieve the necessary improvements due to the reservoir’s chemical and biological problems, including severe manganese and cyanobacteria issues, the utility sought experienced engineering and specialized technology.

Within the first year of implementing Clean-Flo’s solution, cyanobacteria and algal blooms were reduced to such an extent that chemical treatment costs at the water purification plant were halved, as were the levels of TTHMs.